Coninvest’s first professional trip of the year took us to Vienna

There are places where gastronomy is far more than just cooking. Where the kitchen is an engineering system, logistics are a strategy, and hygiene is not an expectation but a basic requirement. The DO & CO logistics center in Vienna is just such a place, and on our first professional trip in 2026, together with canteen operators and party service professionals, we were able to experience firsthand what top-class gastronomy means behind the scenes.

The visit exceeded all our expectations.

The story of a global success from Niki Lauda to global market leadership

The story of DO & CO began with a conversation between friends: Niki Lauda, the Formula 1 legend, suggested to Attila Dogudan that one of the most critical and underrated aspects of flying was the food. This idea eventually gave rise to a global gastronomy and logistics company that now serves around 125,000 people worldwide every day. Not only in the air, but also in stadiums, at world events, exclusive functions, restaurants, and now even in its own hotel and historic café in Vienna. Anyone who has visited their website knows that this world is accompanied by amazing visual quality.

From Formula 1 to cutlery: when gastronomy meets racing cars

The Formula 1 connection is a separate chapter in the story. DO & CO has been the official catering partner of the Formula 1 Paddock Club since 1992, serving the elite of the sport worldwide for more than three decades. Our caterers noted with a smile, “We’ve already seen the new Hungaroring,” referring to how long they have been behind the scenes in the paddock. During the conversations, it was also mentioned that they currently have 62 containers of equipment left in the Middle East because it is simply not worth transporting everything back to Europe before the season starts in Abu Dhabi. This sentence says more about the scale than any statistics.

Vienna is a precisely constructed gastro-logistical machine

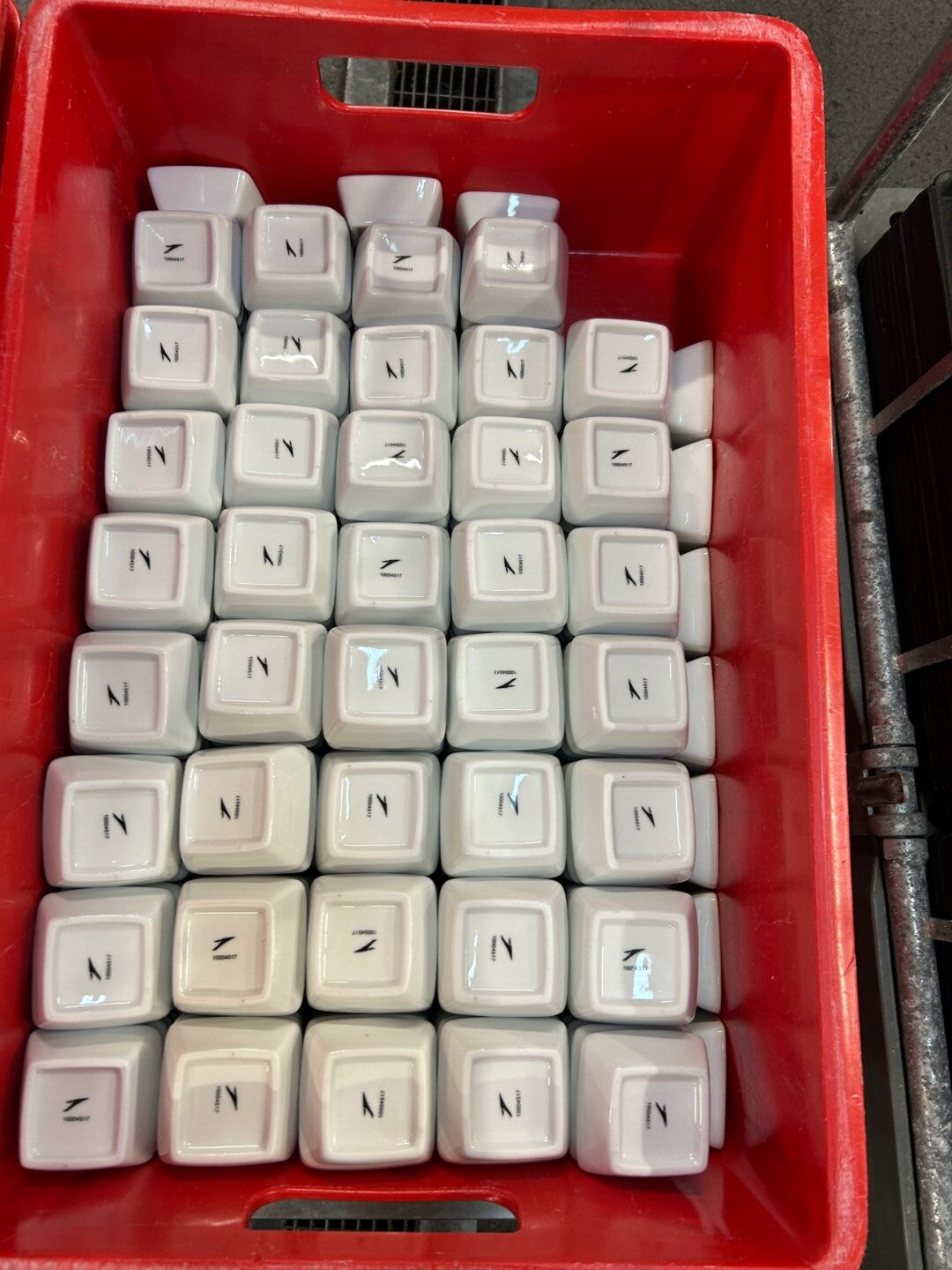

In Vienna, DO & CO’s operations are held together by an extremely precisely structured system: a production kitchen, a 23,000 m² logistics warehouse, and a central dishwashing facility. We were given an exclusive insight into the latter’s operations, and this unit is truly one of the company’s “invisible engines.”

The dishwashing kitchen operates 24 hours a day, in three shifts, every day of the year. Five long-belt MEIKO dishwashing tunnels and a continuously operating in-flight catering trolley washer are in operation here, supervised by a team of around 130 experts. Due to airport catering, the machines must comply with the strictest DIN and hospital hygiene regulations: thermolabel checks, sterile processes, complete traceability. Everything is measurable, everything is documented.

From a technological point of view, the ventilation system in the dishwashing kitchen was particularly interesting: 92,000 m³ of air is exchanged every hour. Despite this, we saw condensation on the windows during our visit. This is a good reminder that even the most sophisticated systems operate at the limits of physics under such extreme humidity loads and continuous operation, and that the design of dishwashing kitchens is now a separate discipline.

They handle 80% of Schwechat Airport’s traffic

DO & CO handles approximately 80% of the traffic at Schwechat Airport. We were able to see the in-flight trolleys, tray systems, and complete logistics processes of Emirates, Delta, and Austrian Airlines up close. One of the dishwashers had a special “Halal” label: only utensils used in halal kitchens can be washed in it, with complete separation. This kind of consistency shows how seriously they take cultural and religious expectations.

Automated cutlery sorting: 5,500 pieces per hour

Washing dishes here is far more than just cleaning. The automated cutlery sorting system processes 5,500 pieces of cutlery per hour, not only separating knives, forks, and spoons, but also sorting them by product family. This is precision logistics, not a background process.

Party Service: when an entire kitchen “moves out”

At the end of the tour, we arrived at the upper floor, where the Party Service division’s maintenance workshop is located.

The numbers here are also impressive:

- 700 combi steamers, which can be deployed for global events

- 50 stainless steel GN refrigerators are scrapped annually

- 27 complete sink tunnel containers

When they go to the ski event in Kitzbühel, for example, where they were just preparing to go, they take a complete dishwashing kitchen with them, because it is more economical to wash dishes on site than to transport 22,000 plates a day between Vienna and Kitzbühel.

Inspiration for us too

This way of thinking was inspiring for us too. The visit confirmed that the future of modern public catering, canteen operation, and party service is not just about good recipes, but also about systematic thinking, technology, and consistent organization.

The DO & CO headquarters in Vienna is one of the best examples of this in Europe. We are proud that on our first professional trip in 2026, we were able to see for ourselves how top-class gastronomy works when the guests have long since gone home. And we are returning with a wealth of lessons and inspiration.