Matteo Gnoato and Mattia Fagherazzi, two Italian kitchen technology experts, arrived in Hungary in mid-April to give a live demonstration of how to work spectacularly and efficiently with Firex’s latest kitchen development, the Cucimix. On the first day of the two-day event held at Coninvest’s showroom in Sóskút, the cream of the Hungarian confectionery industry watched in amazement as the machine, with a capacity of only 30 liters but all the more versatile, demonstrated its capabilities, whether it was making a perfect panna cotta or more complex food preparation processes.

Panna cotta at the touch of a button: when not only the pastry chef but also the machine knows how to make desserts

What is the secret to perfect panna cotta? A precise recipe and a machine that knows exactly what it is doing. Mattia Fagherazzi, corporate chef, and Matteo Gnoato, food industry expert at Firex, demonstrate just that in the Coninvest showroom in Sós-Kút, with the Cucimix smart cooking pot playing the leading role.

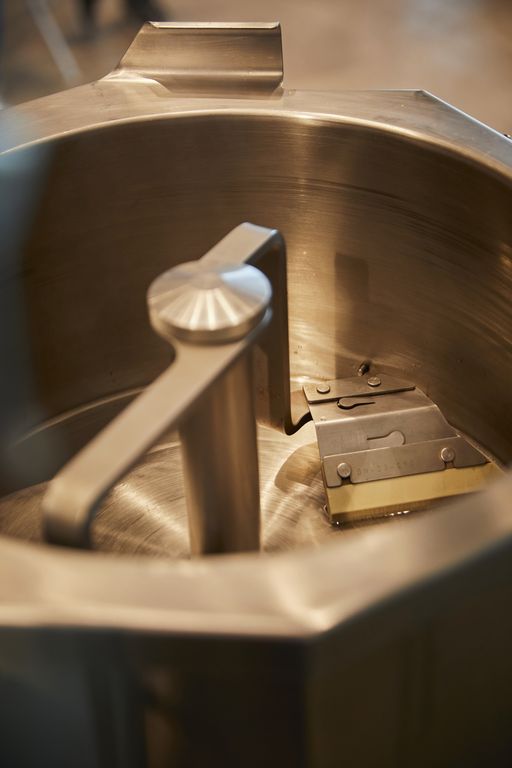

This electrically controlled, direct heating device is currently available in the smallest 30-liter version, but the series also offers capacities of up to 310 liters – powered by gas, steam, or electricity and designed for large-scale use. Under Mattia’s guidance, the mixing arm starts up, milk, cream, sugar and vanilla are added to the pot – and meanwhile, the machine beeps to indicate when it needs which ingredient and in what quantity. Once it has everything it needs, all it takes is a confirmation and it starts working.

“It has two heaters: a heating element at the bottom and, in the confectioner’s version, one on the side as well,” explains the chef. The system mixes automatically, so the dessert doesn’t burn or stick to the bottom of the pot, and you don’t have to stand next to it. What’s more, if everything is OK, the machine beeps to let you know when it’s time to add the gelatin.

Matteo explains that in Italy, as in Hungary, labor shortages in the hospitality industry are becoming an increasing problem. This is where Cucimix comes in: once the master pastry chef has fine-tuned the recipe, the machine can make the perfect panna cotta with almost anyone’s help. Calibrate, check, remove – that’s all the machine operator has to do.

And how easy is it to clean? Quick, efficient, and dead simple. The chef can do it in a few minutes and is ready for the next round, because the machine is ready to go again.

Flawless sugar syrup: where technology and chef expertise come together

The Italian chef doesn’t waste any time: in just a few minutes, the water is boiling for the next cooking task in the Cucimix. He precisely measures the sugar into the modern cooking pot, then sets the temperature to 140 °C – and the sugar syrup is ready. No lemon or other citrus fruit is needed, he says, as the result will be perfectly smooth and free of crystals.

The timer ticks away in the background as Mattia demonstrates live to the professional audience how to intervene in the process as it progresses – speeding it up or slowing it down as needed. However, he warns that this function should remain the privilege of the master confectioner! Trainees only need to program the machine and load the ingredients – the machine can be locked to prevent any intervention that would alter the process.

“As soon as the bubbles disappear from the top of the sugar syrup, we know that the crown of the panna cotta is ready – the perfect caramel,” adds the chef, as he prepares for the next step.

A single machine that can do more than you think: baking, cooking, pasteurizing, and precision kitchen technology all in one

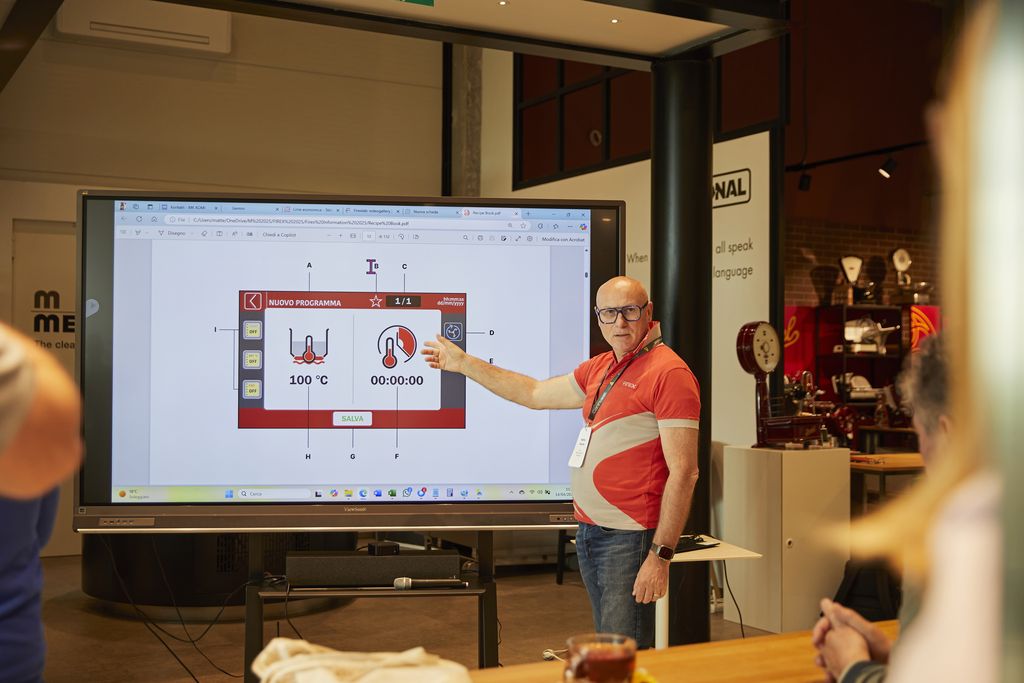

While the caramel and panna cotta rest in the blast chiller, Matteo Gnoato, Firex’s food industry expert, gives a detailed presentation of the Cucimix cooking pot: its different versions, capacities, and how widely it can be used in professional gastronomy. The showroom is filled with intense sweet aromas – the promising delicacy of the dessert can already be sensed in the air. However, the tasting is still to come.

Matteo emphasizes not only the structural advantages of the machine, but also the key role of temperature and time settings, highlighting the use of the core temperature sensor and the surprising ease of communication with the machine. The recipe writing process can be learned by anyone with a detailed instructional video.

Meanwhile, chef Mattia is not idle either: he adds the other garnish for the panna cotta to the machine, a layer of fruit made from strawberries and frozen forest fruits, thickened with sugar and pectin, which also achieves its final consistency in the shock freezer.

Taking advantage of the time saved, Mattia highlights another lesser-known feature: the Cucimix is perfect for pasteurizing – germinating and sterilizing – preserving jars, as proper heat treatment plays a key role in the quality and shelf life of jams.

And finally, the moment arrives: caramel and forest fruit panna cottas are served in small tasting bowls to the expert audience. The room falls silent – everyone is focused on their spoons. The taste and texture are perfect, agree the invited confectioners, adding that working with this machine must be a real pleasure.